Foldable Sleeve Container (FLC)

Foldable Sleeve Container (FLC)Foldable Sleeve Pallet Manufacturers in Pune, Suppliers, Exporters, Dealers in Pune

Sleeve Pallet in Pune

Abha Engineers a renowned sleeve pallet manufacturers, suppliers, dealers, exporters in Pune, takes pleasure in supplying advanced pallet solutions that redefine storage efficiency, being a sleeve pallet manufacturers we know that innovative storage solutions play a critical part in the industrial scene, where efficiency and space optimization are top considerations, our sleeve pallets, precisely developed and built for adaptability, meet the different demands of enterprises, warehouses, and logistics providers.

A sleeve pallet, also known as a collapsible or folding pallet, is a versatile solution designed to optimize storage and transportation efficiency.

It typically features a collapsible structure, allowing the sides to fold down when not in use. This unique design enables space-saving benefits during return shipping or storage, making it an ideal choice for industries with dynamic logistics needs.

Sleeve pallets, sometimes referred to as sleeve pack pallets or sleeve shipment pallets, provide a special and effective way to handle and store a variety of goods, especially ones with big or irregular shapes. They are constructed out of a regular pallet base with a cardboard, plastic, or other material "sleeve" that surrounds it.

Properties

- The Properties of sleeve pallets include their lightweight construction, easy collapsibility, and compatibility with various handling equipment.

- They are often made from durable materials such as plastic or metal, ensuring strength and longevity.

- Sleeve pallets contribute to cost-effective and sustainable supply chain practices by minimizing storage space requirements and reducing return transportation costs.

Sleeve pallets Features

- Sturdy base: Standard wooden or plastic pallet, stable & compatible with existing equipment.

- Cost-effective: Cheaper than custom pallets.

- Lightweight: Reduces transportation costs & improves fuel efficiency.

- Reusable: Some designs allow for multiple uses.

- Stackable: Maximizes storage space & warehouse efficiency.

- Variety of sizes: Accommodates various product dimensions.

Sleeve Pallet Types

1. Single Piece Pallet Sleeves: These provide the highest load capacity and efficient handling. Custom designs ensure optimal volume reduction, and they are easy to set up in seconds.

2. Multi-Part Pallet Sleeves: Perfect for loading and unloading products, these sleeves come in various configurations. They simplify handling, streamline processes, and reduce volume by up to 80%.

Advantages of Our Sleeve Pallets?

Superior Engineering for Maximum Storage -Our reputation as the leading Sleeve Pallet manufacturers comes from our consistent dedication to engineering quality. We offer Sleeve Pallets that excel in durability, load-bearing capability, and space optimization by using innovative production technology and following tight quality control procedures. Our pallets are precision-crafted to optimize storage procedures and maximize warehouse efficiency.

Strategic Supplier Network for Sleeve Pallets-We as top Sleeve Pallet suppliers have built a strategic network; this network enables us to source high-quality raw materials on time, adding to the outstanding quality of our Sleeve Pallets. Working with us as a Sleeve Pallet supplier means that your goods not only satisfy industry requirements but also stand out as preferred options for consumers looking for unique storage solutions.

Joint Ventures-The ease of use of modern storage systems is critical to their broad acceptance. We as Sleeve Pallet dealers ensure that our goods are easily accessible to enterprises, warehouses, and logistics providers through strategic agreements. The partnerships with us Sleeve Pallet dealers make Sleeve Pallets more accessible and allow for easy integration into a variety of storage configurations.

Global Presence as Exporters of Sleeve Pallets-Our dedication to delivering high-quality storage solutions extends beyond the local area. We contribute to global industries as Sleeve Pallet exporters by exporting our products to overseas markets. Our Sleeve Pallets' dependability and adaptability have earned us a worldwide reputation, making us a favored alternative for companies seeking effective storage solutions on a global scale.

Sleeve Pallets: Increasing Storage Efficiency- Spirit Corporation as a leading Sleeve Pallet manufacturer understands the changing storage requirements of industries and logistics suppliers. Our Sleeve Pallets have been exactly developed to complement the city's modern principles, providing an adjustable solution that optimizes space utilization and boosts warehouse efficiency.

Applications

Sleeve pallets find applications across diverse industries, including retail, automotive, and manufacturing. They are particularly advantageous for companies engaged in international trade, as the collapsible design facilitates efficient use of shipping containers.

Additionally, sleeve pallets are favored in industries where storage space optimization and return logistics play pivotal roles, making them a strategic choice for businesses aiming to streamline their operations and reduce environmental impact.

Export Plastic Pallet :

Export Plastic Pallet :

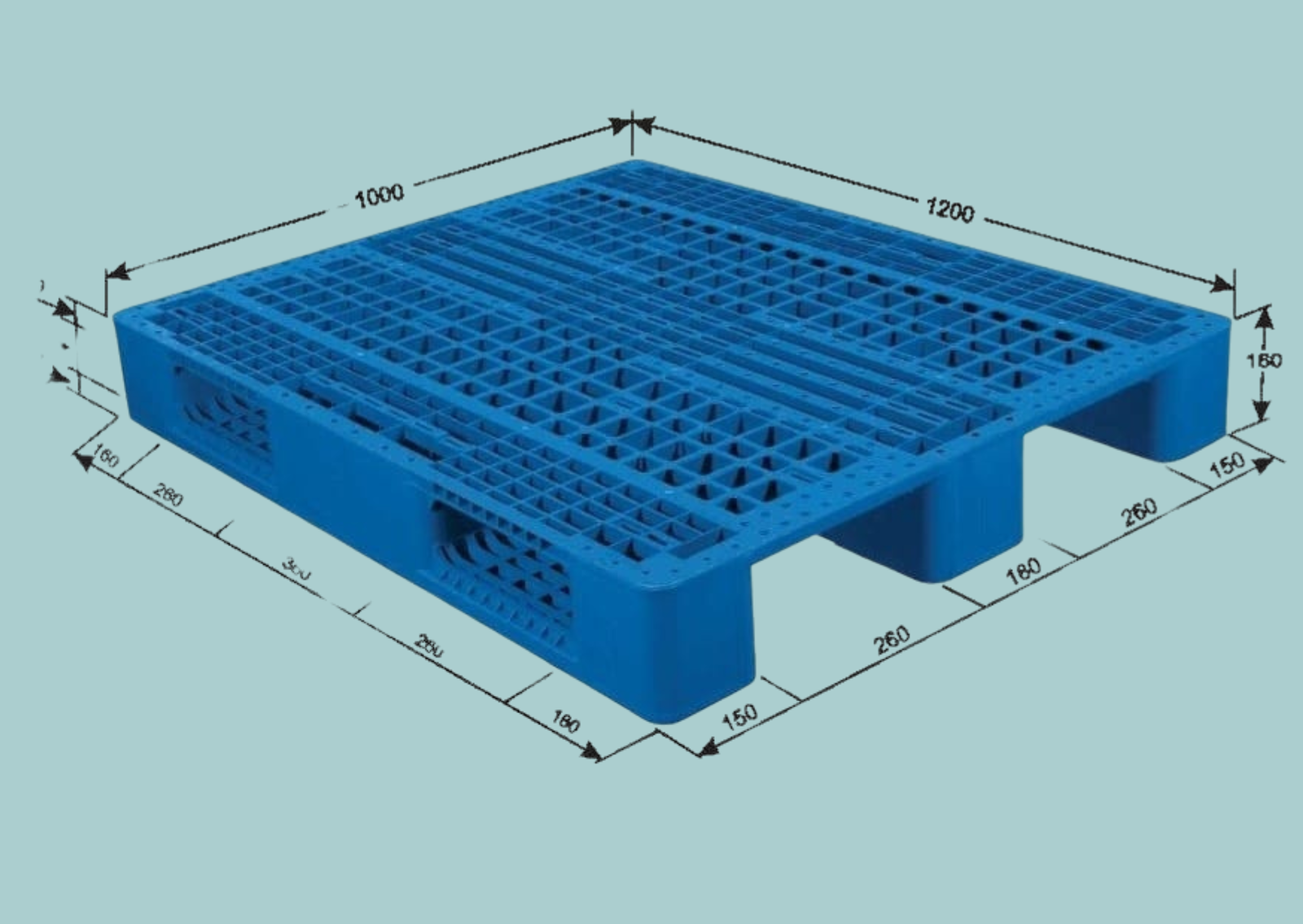

Pallet Size : 1100 x 1100 x 120 mm.

Static Capacity : 2000 Kg

Dynamic Capacity : 1000 Kg.

Color : Black.

Basic Price : 790 Rs.High-Quality Black Plastic Pallets for Export in India

Overview of Black Plastic Pallets

Black plastic pallets are designed to enhance the transportation and storage of goods. They are manufactured using high-density polyethylene (HDPE) or polypropylene (PP), making them durable and resistant to various environmental conditions. These pallets are lightweight yet strong, ensuring the safety and security of products during transit.

Why Choose Black Plastic Pallets?

- Durability: Black plastic pallets are known for their long lifespan and resistance to damage.

- Hygiene: They are easy to clean and do not absorb moisture, preventing contamination.

- Cost-Effectiveness: Their lightweight reduces shipping costs, making them a cost-effective choice.

- Environmental Benefits: They are recyclable and reusable, contributing to sustainability efforts.

Importance of High-Quality Pallets in Export

Using high-quality pallets is crucial in the export industry as they ensure the safe and efficient transportation of goods. Poor-quality pallets can lead to product damage, increased costs, and regulatory issues. Therefore, investing in durable export pallets minimizes risks and enhances the overall efficiency of the supply chain.

Market Demand for Black Plastic Pallets in India

In India, the demand for black plastic pallets has surged due to their numerous advantages over traditional wooden pallets. Industries such as FMCG, automotive, pharmaceuticals, and electronics are increasingly adopting plastic pallets for their export needs, driven by their durability and cost savings.

Types of Black Plastic Pallets

Black plastic pallets come in various types, catering to different needs and applications. This section discusses the material variations, sizes, and shapes available, along with the options of reusable versus disposable pallets and customizable features.

Material Variations

Black plastic pallets are generally made from HDPE or PP. HDPE pallets are known for their strength and rigidity, making them ideal for heavy-duty applications. PP pallets, on the other hand, offer better chemical resistance and are suitable for specific industrial uses.

Different Sizes and Shapes Available

- Standard Size: 1200 x 1000 mm

- Euro Size: 1200 x 800 mm

- Popular Export Size : 1100 x 1100 x 120 mm

- Custom Sizes: Tailored to specific requirements

- Shapes: Nestable, stackable, and rackable designs

Reusable vs. Disposable Pallets

Depending on the application, businesses can choose between reusable and disposable pallets. Reusable pallets are designed for multiple cycles, offering long-term cost savings and environmental benefits. Disposable pallets, on the other hand, are cost-effective for one-time use and can be recycled after use.

Customizable Options

Black plastic pallets can be customized based on specific needs, including custom sizes, shapes, and features such as anti-slip surfaces, increased load capacity, and RFID tags for tracking. Customizable pallets provide flexibility and enhance efficiency in handling and transportation.

Advantages of Using Plastic Pallets for Export

The adoption of plastic pallets for export offers numerous advantages, ranging from durability and cost-effectiveness to hygiene and environmental benefits. This section will explore these benefits in detail.

Durability and Longevity

Black plastic pallets are renowned for their durability and long service life. Unlike wooden pallets, they resist weather elements, chemicals, and physical damage. This longevity ensures a higher return on investment and fewer replacements.

Cost-Effectiveness

While the initial cost of plastic pallets may be higher than wooden pallets, their long-term benefits far outweigh the initial expenditure. They reduce transportation costs due to their lightweight nature and lower the frequency of replacements, offering significant savings.

Hygiene and Cleanliness

Plastic pallets provide a hygienic transport and storage solution. They are easy to clean, resistant to moisture absorption, and prevent the growth of bacteria and fungi. This makes them ideal for industries like pharmaceuticals and food and beverages.

Environmental Benefits

Plastic pallets contribute to sustainability efforts as they are recyclable and reusable. By reducing waste and promoting recycling, businesses can lower their environmental footprint while maintaining efficient operations.

Poly Pallets in India: Durable and Recyclable Plastic Pallets

In recent years, the demand for Poly Pallets in India has surged due to their durability, recyclability, and cost-effectiveness. These industrial plastic pallets are revolutionizing the way various industries handle, store, and transport goods. In this comprehensive guide, we will explore the importance of Poly Pallets, their benefits, applications in different industries, environmental impact, and future trends.

Introduction to Poly Pallets

Poly Pallets are strong, lightweight, and environmentally friendly plastic pallets widely used across various industries. These pallets have evolved over time, offering numerous advantages over traditional wooden pallets.

Overview of Poly Pallets

Poly Pallets are manufactured using high-density polyethylene (HDPE) or polypropylene, providing excellent strength and durability. They are designed to withstand heavy loads and are highly resistant to chemicals, moisture, and impact, making them ideal for industrial use.

Importance of Poly Pallets in Industries

The significance of Poly Pallets in industries cannot be overstated. These pallets ensure safe and efficient handling of goods, reducing the risk of damage and contamination. They also contribute to enhanced workplace hygiene and safety standards.

Types of Poly Pallets

There are various types of Poly Pallets available, including nestable pallets, stackable pallets, and rackable pallets. Each type has its unique features and benefits, catering to different industrial needs and requirements.

Evolution of Poly Pallets

The evolution of Poly Pallets in India has been remarkable. From basic designs to advanced, customizable options, these pallets have continuously evolved to meet the growing demands of modern industries.

Benefits of Using Poly Pallets in India

Using Poly Pallets in India offers numerous benefits such as durability, cost-effectiveness, recyclability, and improved safety and hygiene.

Durability and Longevity

Poly Pallets are known for their exceptional durability and longevity. They can last for several years without any significant wear and tear, making them a reliable option for industrial applications.

Cost-Effectiveness

Although the initial cost of Poly Pallets may be higher than wooden pallets, their long lifespan and low maintenance requirements make them a cost-effective solution in the long run.

Recyclability and Environmental Benefits

Poly Pallets are fully recyclable, contributing to reduced plastic waste and environmental conservation. They can be reprocessed into new pallets or other plastic products, promoting a circular economy.

Safety and Hygiene

Poly Pallets offer significant safety and hygiene benefits. Unlike wooden pallets, they do not splinter or harbor pests, making them suitable for industries with strict hygiene standards like food and pharmaceuticals.

Applications of Poly Pallets in Different Industries

Poly Pallets are extensively used in various industries, each benefiting from the unique properties of these plastic pallets.

Manufacturing Industry

In the manufacturing industry, Poly Pallets are used for transporting raw materials, finished products, and machinery parts. Their durability ensures the safe handling of heavy and bulky items.

Food and Beverage Industry

The food and beverage industry relies on Poly Pallets for their hygienic properties. These pallets reduce the risk of contamination, ensuring that food products remain safe for consumption.

Pharmaceutical Industry

In the pharmaceutical industry, maintaining cleanliness and hygiene is crucial. Poly Pallets are ideal for storing and transporting sensitive medical supplies and pharmaceuticals, adhering to the industry's stringent standards.

Retail and E-commerce

Poly Pallets are also widely used in the retail and e-commerce sectors for efficient logistics and storage. Their lightweight nature and ease of handling simplify the distribution process.

Comparison: Poly Pallets vs. Traditional Wooden Pallets

When comparing Poly Pallets to traditional wooden pallets, several advantages and cost implications come to light.

Advantages of Poly Pallets

Poly Pallets have numerous advantages over wooden pallets, including increased durability, recyclability, and improved hygiene. They are also resistant to chemical and weather damage, which enhances their longevity.

Disadvantages of Traditional Wooden Pallets

Traditional wooden pallets, on the other hand, are prone to splinters, pest infestation, and decay. They require regular maintenance and can pose safety hazards in the workplace due to their potential to break and cause injuries.

Cost Analysis

While the cost of Poly Pallets is higher initially, their longer lifespan and lower maintenance costs result in substantial savings over time. In contrast, wooden pallets may appear cheaper but incur higher replacement and repair costs.

Choosing the Right Poly Pallets for Your Needs

Selecting the right Poly Pallets involves considering various criteria, customization options, and cost factors.

Criteria for Selection

When choosing Poly Pallets, consider factors such as load capacity, pallet design, and intended use. Selecting pallets that meet your specific requirements ensures optimal performance and efficiency.

Customizable Options

Poly Pallets can be customized to suit different industrial needs. Customizable options include size, color, and features like anti-slip surfaces or RFID tracking for better inventory management.

Cost Considerations

Ultimately, consider the total cost of ownership when investing in Poly Pallets. This includes initial purchase price, maintenance costs, and potential savings from their long-term durability and recyclability.

Maintenance and Care for Poly Pallets

Proper maintenance and care of Poly Pallets are essential to ensure their longevity and optimal performance.

Cleaning and Sanitation

Regular cleaning and sanitation of Poly Pallets help maintain hygiene and prevent contamination. Use appropriate cleaning agents and methods based on the industry standards and pallet material.

Regular Inspection and Repairs

Conducting regular inspections helps identify any damage or wear on Poly Pallets, ensuring timely repairs and preventing further issues. Routine checks also contribute to the overall safety and efficiency of pallet use.

Safety Protocols

Implementing safety protocols for handling and using Poly Pallets is crucial. Train employees on proper lifting techniques and pallet stacking methods to minimize the risk of accidents and injuries.

Environmental Impact of Using Poly Pallets

Using Poly Pallets has a positive environmental impact, contributing to recycling efforts, corporate responsibility, and long-term sustainability.

Recycling Opportunities

Poly Pallets are fully recyclable, offering significant recycling opportunities. They can be reprocessed into new pallets or other plastic products, reducing the overall environmental footprint.

Corporate Responsibility

Adopting Poly Pallets reflects a company's commitment to environmental responsibility. By choosing recyclable options, businesses contribute to sustainability and reduce their impact on the environment.

Long-Term Environmental Benefits

The long-term benefits of using Poly Pallets include reducing plastic waste, conserving natural resources, and promoting sustainable practices within industries. These benefits support conservation efforts and protect the planet for future generations.

Innovations and Future Trends in Poly Pallets

The future of Poly Pallets is promising, with continuous innovations and the adoption of new materials, smart technologies, and sustainable practices.

New Materials and Technologies

Advancements in material science and technology are introducing new, stronger, and more sustainable materials for Poly Pallets. These innovations enhance pallet performance and durability.

Smart Pallets

Smart Pallets with integrated RFID and IoT technologies are emerging as a trend. These pallets enable real-time tracking, better inventory management, and efficient logistics operations.

Sustainable Practices

Companies are increasingly adopting sustainable practices, focusing on using recycled materials and eco-friendly manufacturing processes for Poly Pallets. This shift towards sustainability aligns with global efforts to reduce carbon footprints.

Market Growth in India

The market for Poly Pallets in India is growing rapidly. With the increasing demand for efficient and sustainable solutions, more industries are recognizing the benefits of Poly Pallets and making the switch from traditional wooden pallets.

Conclusion

In conclusion, Poly Pallets in India provide a durable, recyclable, and cost-effective solution for various industries. With their numerous benefits, including enhanced durability, recyclability, and improved hygiene, they are a superior alternative to traditional wooden pallets. As industries continue to prioritize sustainability and efficiency, the demand for Poly Pallets is expected to increase, driving innovation and market growth in the coming years.

Recycle Plastic Heavy Duty Pallet

Recycle Plastic Heavy Duty PalletMega Recycle Plastic Heavy Duty Racking Pallets in India – Top Quality

In today's logistics and supply chain industry, the use of heavy duty racking plastic pallets has become increasingly significant. These pallets are not only versatile and durable but also offer numerous benefits across varied industries. This comprehensive article will delve into various aspects of heavy duty rackable plastic pallets, their importance in logistics, and their advantages. We will also explore the types of rackable pallets, standards and regulations, top manufacturers in India, and future trends in this sector.

Introduction to Heavy Duty Rackable Plastic Pallets

Overview of Rackable Pallets

Mega Recycle Plastic Rackable pallets are specifically designed to be used with racking systems, providing stability and support for heavy loads. These pallets come with features such as anti-slip surfaces, making them ideal for use in warehouses and distribution centers. Their robust design ensures that they can handle the stress of heavy-duty operations.

Benefits of Using Mega Recycle Plastic Pallets

Recycle Plastic pallets offer numerous advantages over traditional wooden pallets. Some of the key benefits include:

- Durability: Plastic pallets are resistant to moisture, chemicals, and impact.

- Hygiene: They are easy to clean and do not harbor pests or fungi.

- Cost-Effectiveness: Despite a higher upfront cost, plastic pallets have a longer lifespan.

- Environmental Impact: Plastic pallets are recyclable and contribute to sustainability efforts.

Applications in Different Industries

Heavy duty rackable plastic pallets find applications in various industries. In the FMCG sector, they are used for storing and transporting goods efficiently. In the pharmaceutical sector, their hygienic properties are highly valued. The automotive industry uses these pallets for handling heavy parts and components, while the retail supply chain benefits from their lightweight and stackable design.

Types of Rackable Pallets

Customizable Rackable Pallets

The versatility of Recycle plastic pallets allows for customization to meet specific needs. Customizable rackable pallets can be tailored in terms of size, design, and load capacity. This flexibility is particularly beneficial for industries with unique storage or transportation requirements.

Advantages of Heavy Duty Plastic Pallets

Durability and Longevity

One of the primary advantages of heavy duty plastic pallets is their exceptional durability. These pallets can withstand harsh conditions without warping, cracking, or splintering. Their longevity means fewer replacements are needed, providing significant cost savings over time.

Cost-Effectiveness

Although the initial investment for plastic pallets may be higher, their long-term cost-effectiveness is unmatched. Reduced maintenance, fewer replacements, and their lightweight nature decrease shipping costs, making them a financially sound choice for businesses.

Safety and Hygiene

Plastic pallets are designed with safety and hygiene in mind. They are easy to clean, non-porous, and do not support the growth of bacteria or fungi. This makes them ideal for industries where hygiene is paramount, such as food and pharmaceuticals.

Environmental Impact

Recycle Plastic pallets contribute positively to the environment by being fully recyclable. They reduce the demand for wood, thereby conserving forests. Many manufacturers also use recycled plastic to produce new pallets, further supporting sustainability efforts.

Standards and Regulations for Rackable Pallets in India

ISPM 15 Regulations

The International Standards for Phytosanitary Measures No. 15 (ISPM 15) provides guidelines for treating wooden pallets to prevent the spread of pests. Plastic pallets, however, do not require such treatments, making them a safer and more compliant choice for international shipping.

BIS Standards

In India, the Bureau of Indian Standards (BIS) sets the guidelines for the quality and specifications of plastic pallets. Compliance with BIS standards ensures that the pallets are reliable, durable, and suitable for their intended use.

Global Compliance

For businesses involved in international trade, adherence to global standards is crucial. Plastic pallets that meet international certifications, such as ISO and ASTM, offer assurance of quality and acceptance in international markets.

Quality Assurance Practices

Quality assurance practices, including rigorous testing and quality checks, are essential to ensure that plastic pallets meet the required standards. These practices help in maintaining consistency, reliability, and customer satisfaction.

Choosing the Right Rackable Pallets

Factors to Consider

When selecting heavy duty rackable plastic pallets, consider factors such as load capacity, pallet size, type of goods, and the racking system used. Evaluating these factors will help in choosing the most suitable pallets for specific needs.

Cost vs. Benefit Analysis

Conducting a cost vs. benefit analysis is crucial. Despite a higher initial cost, heavy duty plastic pallets offer long-term savings due to their durability, fewer replacements, and reduced maintenance costs. Weighing these benefits against the costs will inform better purchasing decisions.

Customization Options

Opting for customizable rackable pallets can provide solutions tailored to specific logistics needs. Customization options include altering dimensions, adding anti-slip surfaces, and incorporating RFID tags for better tracking and management.

Case Studies: Successful Implementation of Recycle Plastic Heavy Duty Rackable Pallets

Case Study 1: FMCG Industry

In the FMCG industry, a leading manufacturer adopted rackable plastic pallets to streamline its supply chain. The result was improved efficiency, reduced product damage, and lower transportation costs.

Case Study 2: Pharmaceutical Sector

A pharmaceutical company faced challenges with hygiene and safety. Switching to hygienic plastic pallets helped them maintain strict sanitary standards while enhancing storage and handling efficiency.

Case Study 3: Automotive Industry

An automotive giant utilized durable plastic pallets to handle heavy, bulky parts. The pallets proved to be resilient, reducing replacement costs and ensuring the safe transport of components.

Case Study 4: Retail Supply Chain

A major retailer implemented rackable plastic pallets across its supply chain. The lightweight and stackable design facilitated easy movement and optimized storage, leading to significant operational improvements.

Heavy Duty Injection Molded Plastic Pallet Racking , Stacking and floor Application.

Heavy Duty Injection Molded Plastic Pallet Racking , Stacking and floor Application.

Available Sizes :

1) 1200 x 1000 x 170 mm.

2) 1200 x 800 x 170 mm.

3) 1200 x 1200 x 170 mm.

4) 1100 x 1100 x 130 mm. ( Export Pallet )

5) 1200 x 1200 x 170 mm. ( Steel Reinforcement )

etc ...

Injection Molded Pallets | Heavy-Duty, Customizable & Hygienic Plastic Pallets for Sale

Top-rated injection molded pallets for logistics, food, pharma & automotive industries. Durable, FDA-compliant, nestable & recyclable. Get a quote from trusted plastic pallet manufacturers!

www.customplasticpalletsolution.co.in: /injection-molded-pallets

Premium Injection Molded Pallets – Durable, Hygienic & Cost-Effective Solutions**

Injection molded pallets are the modern answer to heavy-duty logistics, warehousing, and supply chain challenges. Built from high-performance polymers like HDPE and polypropylene, these plastic pallets outperform traditional wood and metal options in durability, hygiene, and ROI. At Abha Engineers, we specialize in manufacturing custom plastic palletstailored to industries ranging from food processing to automotive manufacturing.

Why Choose Injection Molded Plastic Pallets?

Heavy-Duty Performance:

Engineered to handle up to 1500 Kg.

of dynamic load capacity, ideal for automotive parts, machinery, and bulk goods.

Hygienic & FDA-Compliant:

Non-porous, easy-to-clean surfaces prevent bacterial growth – perfect for

food-grade plastic pallets and pharmaceutical plastic pallets.

Weather & Chemical Resistant: Withstand extreme temperatures (-40°F to 230°F), moisture, and corrosive substances.

-Lightweight & Nestable : 30% lighter than wood, reducing shipping costs. Nestable designs save up to 75% storage space.

Eco-Friendly & Recyclable: 100% recyclable materials align with sustainability goals.

Customizable Plastic Pallets : Choose sizes, colors, anti-slip textures, RFID tags, and reinforcement options.

Applications of Injection Molded Pallets

Logistics & Warehousing Pallets :

Compatible with forklifts, conveyors, and automated systems.

Food & Beverage:

FDA-compliant plastic pallets for contamination-free transport.

Pharmaceuticals : Hygienic, easy-to-sanitize designs for clean room compliance.

Automotive:: Heavy-duty pallets for engines, parts, and assembly lines.

Agriculture & Chemicals: Corrosion-resistant pallets for fertilizers, pesticides, and liquids.

Key Features of Our Plastic Pallets**

High-Density Polyethylene (HDPE):** Superior impact resistance and UV stability.

Polypropylene (PP):** Excellent chemical resistance for harsh environments.

Anti-Slip Surfaces:** Textured decks prevent load shifts.

Reinforced Legs:** Steel or fiberglass reinforcements for heavy loads.

Fire-Retardant Options:** Meet safety standards for high-risk industries.

Industries We Serve:

Food & Beverage:Hygienic plastic pallets with NSF/ISO certifications.

Pharmaceuticals: GMP-compliant designs for sterile environments.

Automotive: Heavy-duty pallets for Just-In-Time (JIT) manufacturing.

Retail & E-Commerce: Nestable, space-saving pallets for warehouses.

Chemicals: Corrosion-resistant pallets for drums and bulk liquids.