Custom Build Plastic Pallet

"Sustainable

Strength, Custom-Fit, Repairable, Recycle Plastic Pallet Solutions."

Solve your unique storage challenges with our Customized recycled plastic pallets. Engineered precisely for spools, reels, and circular items, these eco-friendly and durable solutions ensure secure, efficient handling. Say goodbye to damaged goods and wasted space – invest in tailored sustainability for your unique products.

Our durable, eco-friendly solutions are perfect for sustainable logistics. We offer customize plastic pallets tailored to your specific needs, ensuring optimal fit and functionality. Plus, our repairable plastic pallets extend lifespan, reducing waste and costs. Choose us for robust, sustainable, and adaptable pallet solutions.

Our durable, eco-friendly solutions are perfect for sustainable logistics. We offer customize plastic pallets tailored to your specific needs, ensuring optimal fit and functionality. Plus, our repairable plastic pallets extend lifespan, reducing waste and costs. Choose us for robust, sustainable, and adaptable pallet solutions. Optimize your logistics with our customize, repairable & recycle plastic pallets. Our innovative designs offer easy to assemble and disassemble plastic pallets, Choose sustainability with ourrecycle plastic pallets, minimizing environmental impact.

Optimize your logistics with our customize, repairable & recycle plastic pallets. Our innovative designs offer easy to assemble and disassemble plastic pallets, Choose sustainability with ourrecycle plastic pallets, minimizing environmental impact.

In India's growing logistics,buy reliable plastic pallets for durability and efficiency.Plastic pallets for sale offer a hygienic, cost-effective alternative to wood.

Export Plastic Pallet available in Best Price.

Export Plastic Pallet available in Best Price.

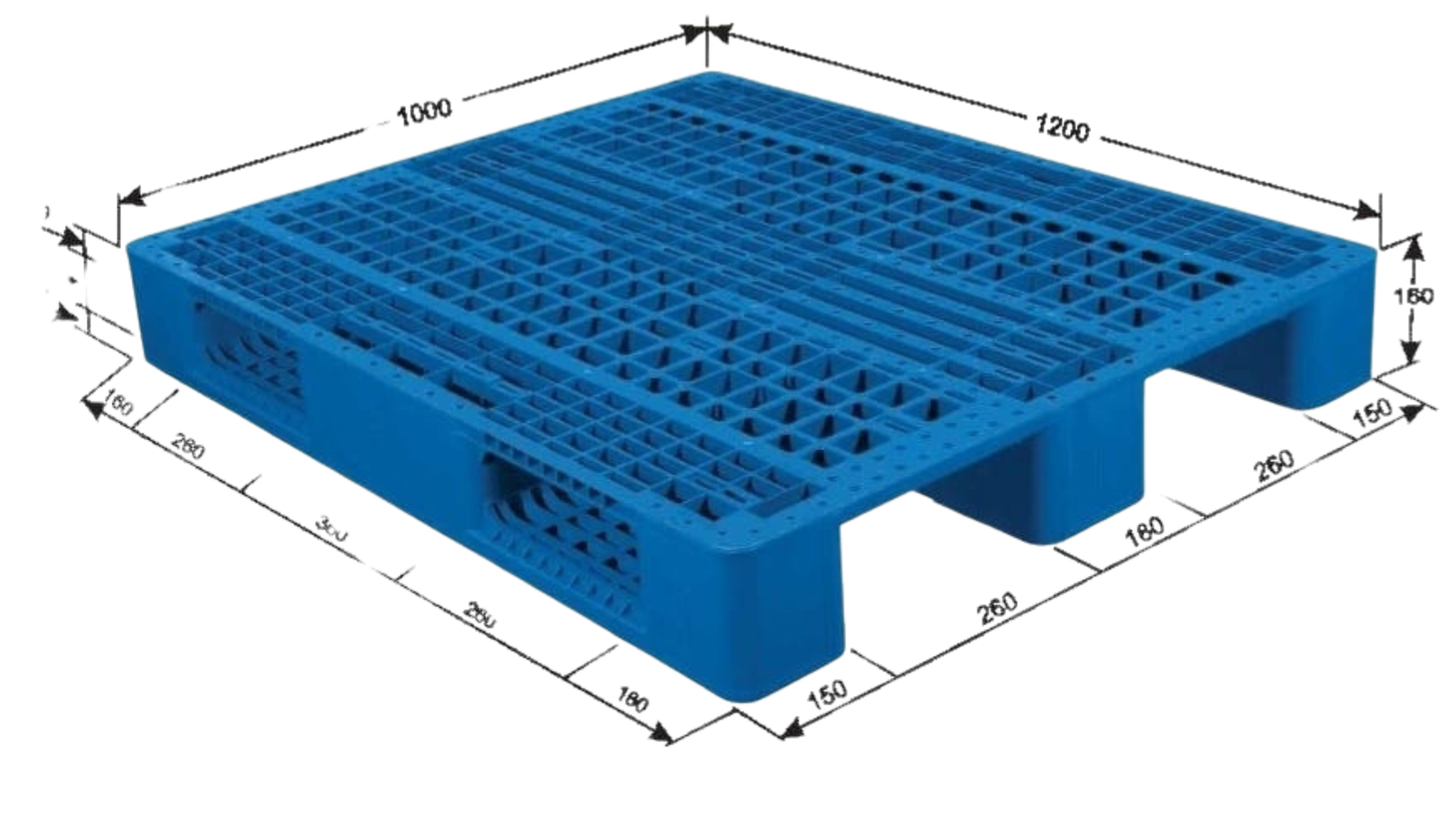

Pallet size : 1100 x 1100 x120 mm.

Load capacity :

Static Load : 2000 kg.

Dynamic Load : 1000 Kg.

Best Price : 810 Rs. Industrial plastic crate in all sizes for storage and transportation of material with partition for Industries.

Industrial plastic crate in all sizes for storage and transportation of material with partition for Industries. Pallet Sleeve Box for storage and Transportation. Available in 1200 x 1000 x 1000 mm, 1200 x 800 x 1000 mm Sizes.

Pallet Sleeve Box for storage and Transportation. Available in 1200 x 1000 x 1000 mm, 1200 x 800 x 1000 mm Sizes.

Why Go Recycled? The Power of Sustainable Pallets

Our recycled plastic pallets are crafted from repurposed plastic waste, offering a robust and environmentally responsible alternative to traditional wooden or virgin plastic options. They're designed for exceptional durability, strength, and longevity, making them the ideal choice for a diverse range of industries.

Here's why they stand out:

- Positive Environmental Impact: By choosing recycled pallets, you directly contribute to reducing plastic waste, conserving precious natural resources, and minimizing your overall environmental footprint.

- Serious Cost-Effectiveness: While there might be an initial investment, the long-term savings are significant. Our pallets boast low maintenance needs and exceptional durability, translating to fewer replacements and lower operational costs over time.

- Unmatched Durability & Longevity: Built tough, these pallets can withstand the harshest conditions and heaviest loads. Say goodbye to splintering, rotting, and the need for chemical treatments.

Recycled vs. Virgin: A Clear Winner

When it comes to performance and value, recycled plastic pallets consistently outperform their virgin counterparts. They deliver high performance and impressive durability, often matching or even exceeding the capabilities of pallets made from new plastic. Plus, their versatility makes them perfect for various sectors, including retail, manufacturing, and pharmaceuticals.

Seamless Integration into Your Supply Chain

Transitioning to recycled plastic pallets is a smart move for enhanced efficiency and sustainability. We recommend a two-step approach:

- Assess Your Current Practices: Let's look at your existing pallet usage and material handling processes to pinpoint areas where recycled pallets can make the biggest impact.

- Strategic Planning & Integration: We'll help you set clear sustainability goals, establish effective procurement strategies, and design a smooth roadmap for integrating recycled pallets into your operations.

Many companies across India are already experiencing the significant benefits of this switch, from improved supply chain efficiency to considerable cost savings.

The Bright Future of Pallets in India

The market is clearly embracing recycled plastic pallets. Growing awareness of their environmental benefits and long-term economic advantages is driving this trend, with more and more businesses opting to move away from wooden pallets.

Beyond the cost savings, consider the environmental gains:

- Massive Reduction in Plastic Waste: We're talking about repurposing plastic that would otherwise end up in landfills, contributing to a cleaner, healthier environment.

- Lower Carbon Footprint: The recycling process uses less energy and produces fewer greenhouse gas emissions compared to virgin plastic production.

- Resource Conservation: By using recycled materials, we help conserve valuable natural resources like crude oil and natural gas.

Customization and Cost-Effectiveness: A Winning Combination

Investing in customized recycled plastic pallets offers significant long-term savings. While the initial outlay might be a bit more than wooden pallets, the return on investment is undeniable.

- Minimal Maintenance Costs: No more worrying about ongoing upkeep, repairs, or replacements due to rot or damage.

- Favorable ROI: Expect reduced handling costs, less product damage, and lower replacement rates, all contributing to a strong return on your investment.

Diverse Applications Across Indian Industries

Our customized recycled plastic pallets are becoming the go-to solution for their versatility and sustainability across various sectors in India:

- Warehouses: Ideal for hygienic storage and transport of goods, minimizing contamination and waste.

- Manufacturing: Perfect for robust internal and external transport of raw materials and finished products.

- Food & Beverage: Ensures the highest levels of hygiene and prevents spoilage.

- Pharmaceuticals: Crucial for maintaining strict cleanliness and contamination control standards.

Choosing the Perfect Pallet: We're Here to Help

Selecting the right recycled plastic pallet means ensuring it perfectly aligns with your operational needs and delivers maximum value. Start by assessing your specific requirements, including the necessary load capacity, environmental conditions, and intended use.

Ready to explore how heavy-duty recycled plastic pallets can revolutionize your industrial operations? Let's discuss your needs!

Heavy Duty , Hygienic and Eco Friendly -our Fabricated Recycles Plastic Pallets Deliver Strength, Savings, and Sustainability for Every Industry.

Solve your unique storage challenges with our customized recycled plastic pallets. Engineered precisely for spools, reels, and circular items, these eco-friendly and durable Plastic Pallet solutions ensure secure, efficient handling. Say goodbye to damaged goods and wasted space – invest in tailored sustainability for your unique products.

There are various types of customized recycled plastic pallets available to suit different industrial needs, each offering unique features and benefits.

One-Way Pallets

Multi-Use Pallets

Heavy-Duty Pallets

Racking Pallets

Topic: Extending the Lifespan of Industrial Pallets

Maximize your pallet lifespan with our recycle plastic pallet video: how to assemble and repair easily. Learn to quickly assemble and maintain our eco-friendly pallets, reducing waste and costs. This comprehensive guide demonstrates the simple steps for both assembly and repair, ensuring your recycle plastic pallets stay in optimal condition. Discover how to extend pallet usage and contribute to a sustainable supply chain. Our video showcases easy-to-follow techniques for both assembly and repair, making maintenance a breeze. See how simple it is to keep your pallets functional and eco-conscious. Watch our recycle plastic pallet video now for practical tips on assembly and repair, ensuring long-lasting performance and sustainability.“Where to Buy High-Quality Recycled Plastic Pallets in Pune

This blog is a comprehensive guide for companies looking to source high-quality recycled plastic pallets for storage, transportation, or export. It explores the advantages of choosing recycled pallets over wood or virgin plastic options, such as long-term durability, hygiene benefits, and environmental impact.

The article outlines key criteria for evaluating pallet quality, including weight load, material composition, and compliance with international standards. It then highlights the best places to purchase these pallets — from local manufacturers and online B2B marketplaces to trusted industrial suppliers. Practical tips for negotiating bulk purchases, understanding certifications, and avoiding poor-quality products are also included.

This blog is tailored for decision-makers in warehousing, supply chain, cold storage, food processing, and pharma logistics, helping them make informed and sustainable pallet sourcing decisions.

- 26

- ganesh bangale

- 16 Jul

Recycle Plastic Pallet vs Wooden & Virgin Plastic Pallet which is Better for your business

- 6

- ganesh bangale

- 16 Jun

Recycled Pallets: The Smart Choice for Industrial Storage & Movement in India

- 142

- ganesh bangale

- 16 Jun

Sustainable Strength: Why Recycled Plastic Pallets Are the Future of Industrial Logistics

- 151

- ganesh bangale

- 16 Jun